Dipl. Ing. Arch. Kathleen Schremmer-Torresi

Geschäftsführende Gesellschafterin

Mit dem Know-how aus über 25 Jahren Erfahrung entwickeln wir für jeden Kunden die optimale Lösung im Bereich der industriellen Prozesskühlung.

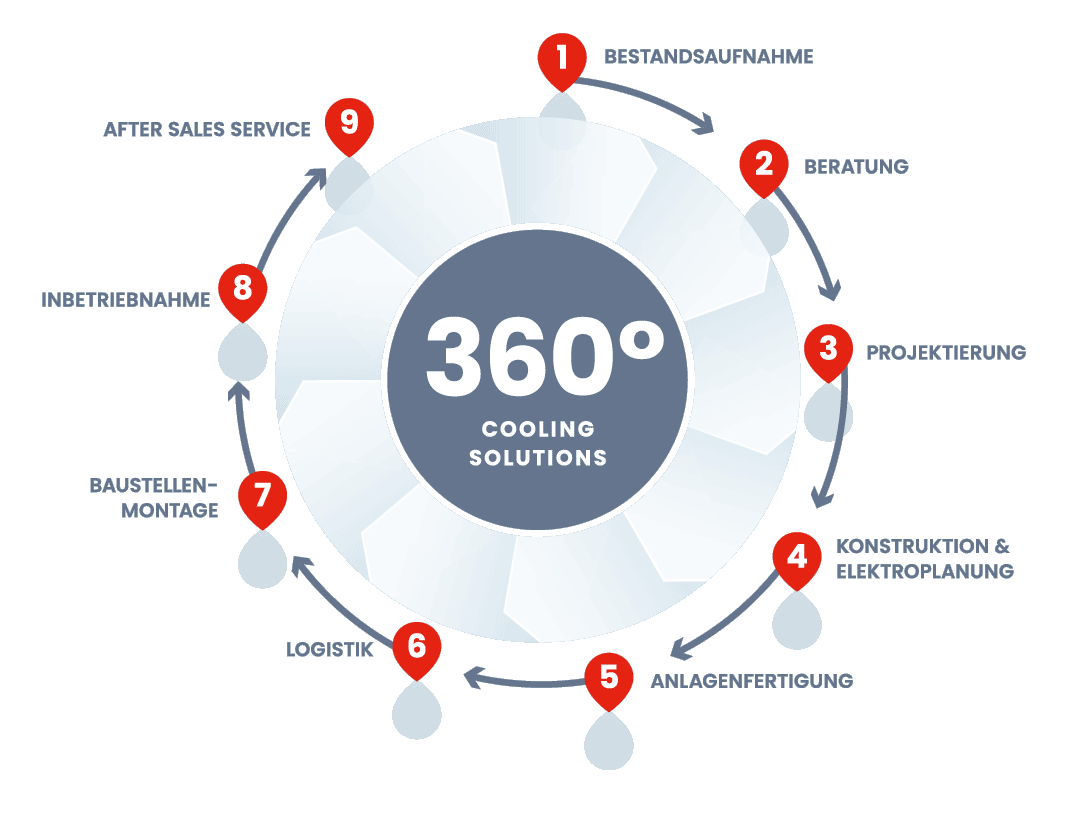

Von der Lieferung einzelner Komponenten bis zur Durchführung von Gesamtprojekten liegt bei MULTI Kühlsysteme die Bestandsaufnahme, Gesamtplanung, technische Bearbeitung, Fertigung, Montage, Steuerung mit Programmierung, Inbetriebsetzung und After Sales Service in einer Hand.

Je kniffliger die Herausforderung, desto ambitionierter machen wir uns an die Arbeit. Das gilt für die Ingenieure der Planung ebenso wie für unsere Monteure und Elektriker in der Fertigung. Wir suchen für Sie die optimale Lösung und garantieren maximale Verbindlichkeit im Prozess.

Wenn es darum geht, die beste Lösung zu finden, schöpfen wir aus den Vollen. Wir bieten Kühlanlagen und Kühltürme komplett aus einer Hand. Sie teilen uns einfach Ihren Kühlbedarf mit und erhalten von uns auf Wunsch das Rundum-Sorglos-Paket zur Abführung überschüssiger Wärme.

Ein dauerhaft zuverlässiger Betrieb Ihrer Kühllösung ist für den Betrieb Ihrer Anlage unabdingbar. Unser Service übernimmt die Wartung mit speziell geschultem Personal im Bereich der Wasserchemie und im Umgang mit Dosiermitteln, um einen störungsfreien Betrieb Ihrer Geräte und Kühlsysteme selbst unter extrem harten Bedingungen zuverlässig zu gewährleisten. Auf Wunsch übernehmen wir auch die rechnergestützte Fernwartung Ihrer Systeme.

25 Jahre

1.100 Kühlsysteme

> 700 zufriedene Kunden

Wir wünschen unseren Kunden, unseren Mietern und Kollegen, frohe und friedliche Osterfeiertage!

Ab sofort verkaufen wir unsere Dosiermittelkanister mit 10% Sonderrabatt.

Die Rabattaktion endet am 15.02.2024.

Das betrifft alle „MULTI Kanister“:…

Die richtige Kühlanlage spart Ihnen Zeit, Geld und Nerven. Wir helfen Ihnen, die optimale Lösung für Ihre Anlage zu finden.